It may not have made major headlines, but earlier this month a story broke that demonstrates how 3D printing is making a huge impact in the medical industry. A sea turtle that had been injured colliding with a motor boat had its beak replaced with a 3D printed prosthetic. Providing the part is not rejected, the turtle could even be allowed to return to the sea.

However, 3D printing has potential health benefits to humans too, many of which we are currently discovering. Earlier this month, for example, cosmetics firm L’Oreal announced a partnership with Organovo to 3D print human skin. Although the collaboration is for use in the beauty industry, the overlaps of biology and 3D printing could provide benefits for burns victims and those suffering from skin conditions.

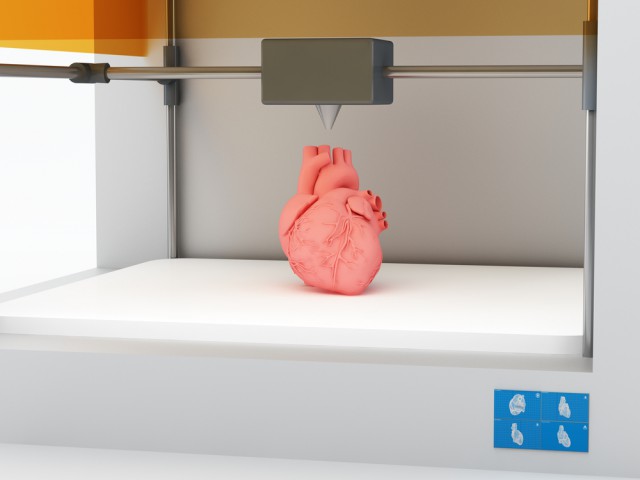

Research is currently being conducted into the possibility of 3D printers being able to replicate the complex organs that sustain our bodies. Researchers at Princeton University have successfully printed a prototype outer ear from hydrogel, human cells and silver nanoparticles. Tailor made joints and bones can also be produced.

In fact, the ability to produce personalized medical solutions is one of the main advantages of 3D-printing. Unique parts are usually costly and time consuming to produce, but when printers are combined with the 3D imaging techniques already being used by the health industry, this becomes a more viable solution.

Considering the idea of 3D printing a human organ still sounds like it belongs to the world of science fiction, the technology is making great strides. In 2014, printed body parts made up sales in excess of $500 million.

However, there are still a number of hurdles to be overcome before we can consider 3D printers as means of full organ replacement. Currently, the most advanced research surrounding internal organs is only able to produce partial tissue samples suitable for testing, and Jennifer Lewis, a bioengineer at Harvard University, believes the industry may never provide a perfect solution to organ replacements.

"I would love for that to be true", she says. "But these are highly complicated architectures".

Despite the reservations, 3D printing is already providing significant benefits to the health industry. Earlier this year, a two-year-old girl born with a serious heart defect underwent a life-saving operation to patch a hole between her ventricles. The patch had to be constructed with the upmost precision, so doctors at St. Thomas Hospital, London turned to 3D printing to ensure the operation was a success.

3D printers are also being used to provide prosthetics at a much lower cost than previously possible. Prosthetics for certain parts of the body, such as the hands, are subject to so much wear and tear that the cost of producing them, sometimes as much as $10,000, can be prohibitive. Similarly, for young children who can outgrow their prosthetics in just a few months, traditional methods of producing replacement limbs are not practical. By contrast, 3D printers can be used to produce customizable prosthetic hands for a few hundred dollars, making them accessible to a much larger proportion of patients.

The technology can also be used in less obvious ways to aid the medical industry. Scientists have found that printing cells enables them to carry out tests in a more systematic environment, which allows for more effective testing of treatments. This approach has been trialled by students at Harvard University Medical School on tumor cells.

The most obvious potential for 3D printing may be in the manufacturing industry, but the technology has a variety of uses, some that we are yet to discover. Whether or not 3D printers are eventually able to produce fully functioning organs is impossible to say, but the healthcare industry is already benefitting immensely from this relatively new technology.

Published under license from ITProPortal.com, a Net Communities Ltd Publication. All rights reserved.

Photo Credit: belekekin/Shutterstock