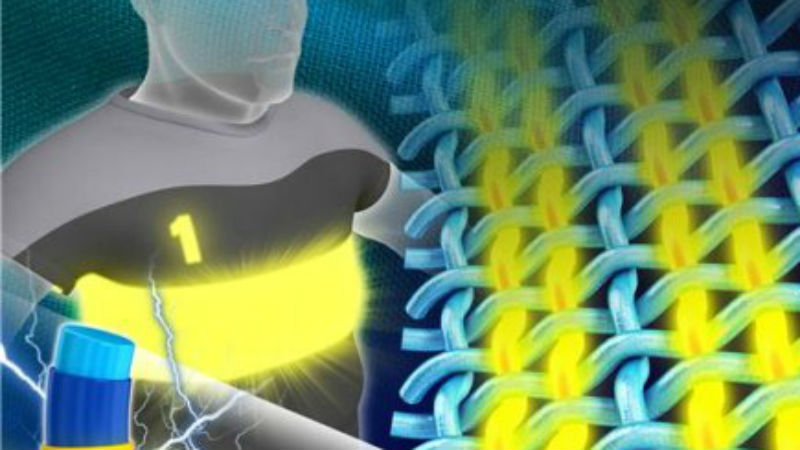

Researchers at the Korea Advanced Institute of Science and Technology (KAIST) have created a fiber-like LED that can be directly woven to create wearable fabric.

In plain terms, Korean scientists have created bendable wearable displays.

"Our research will become a core technology in developing light emitting diodes on fibres, which are fundamental elements of fabrics,” said Professor Choi, head of the research team at the School of Electrical Engineering at KAIST. “We hope we can lower the barrier of wearable displays entering the market".

The process of making this fabric involves a lot of dipping and drying and is, as researchers claim, a much more efficient way of applying LED materials to small cylindrical structures than any heat-treating method.

Gizmag has the details: "The scientists start with a fiber of polyethylene terephthalate, which they then dip several times into a solution of PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) and then dry at 130° C (266° F) for 30 minutes to ready it for layering with organic materials. Once dried, the dipped fiber is then re-dipped in a bath of super-yellow (poly-(p-phenylenevinylene) polymer organic LED (OLED)) solution, dried again in an oven, and finally coated with a Lithium Fluoride/Aluminum (LiF/Al) compound".

The researchers believe this will speed up the process of creating wearable displays as this process is simple, cheap and effective. LED fibers could be mass-produced as easily as nylon or polyethylene fiber is produced today.

"This technology will eventually allow the production of wearable displays to be as easy as making clothes", said Seon-Il Kwon, a member of the KAIST Electrical Engineering team.

Published under license from ITProPortal.com, a Net Communities Ltd Publication. All rights reserved.